THE PROCESS OF LASER CUTTING

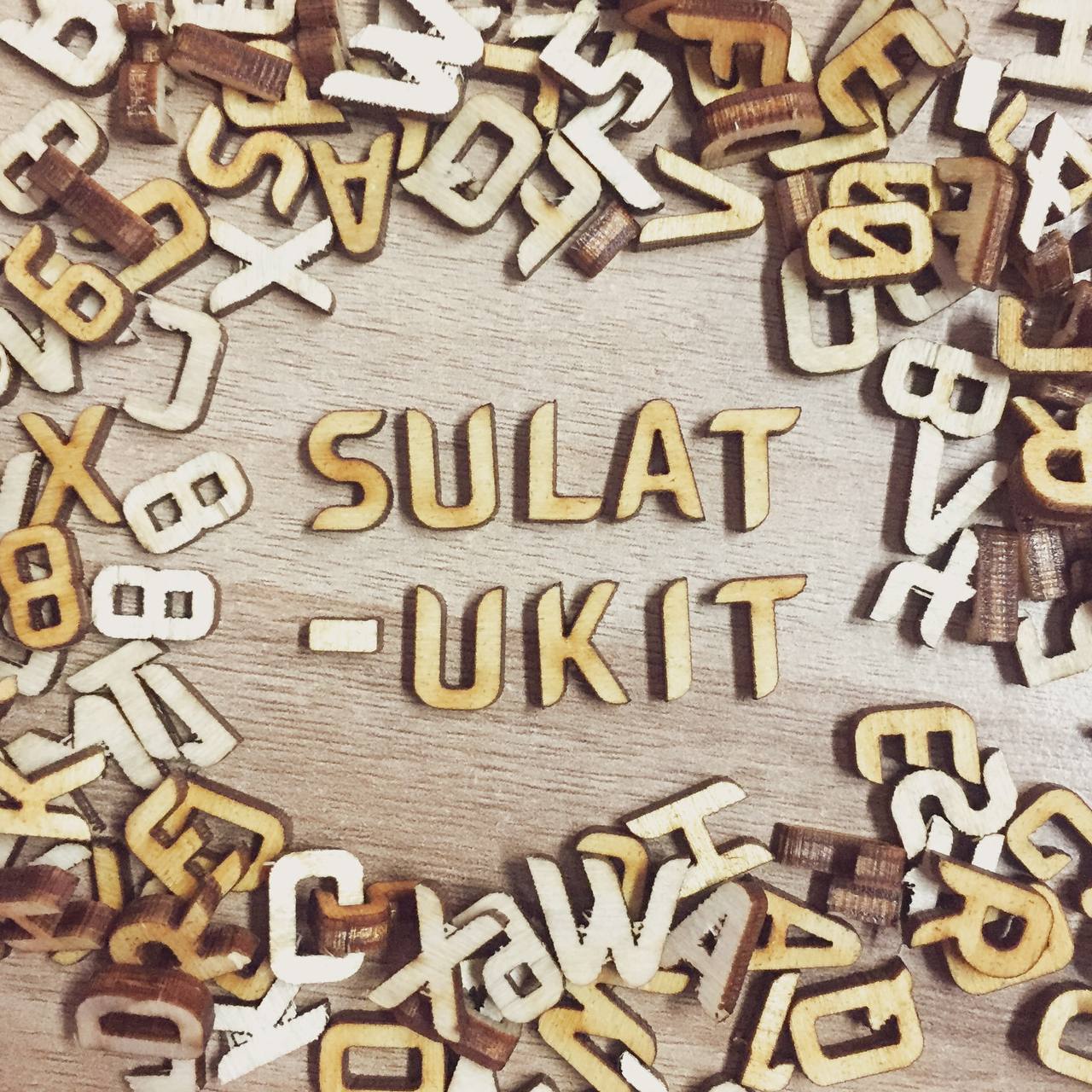

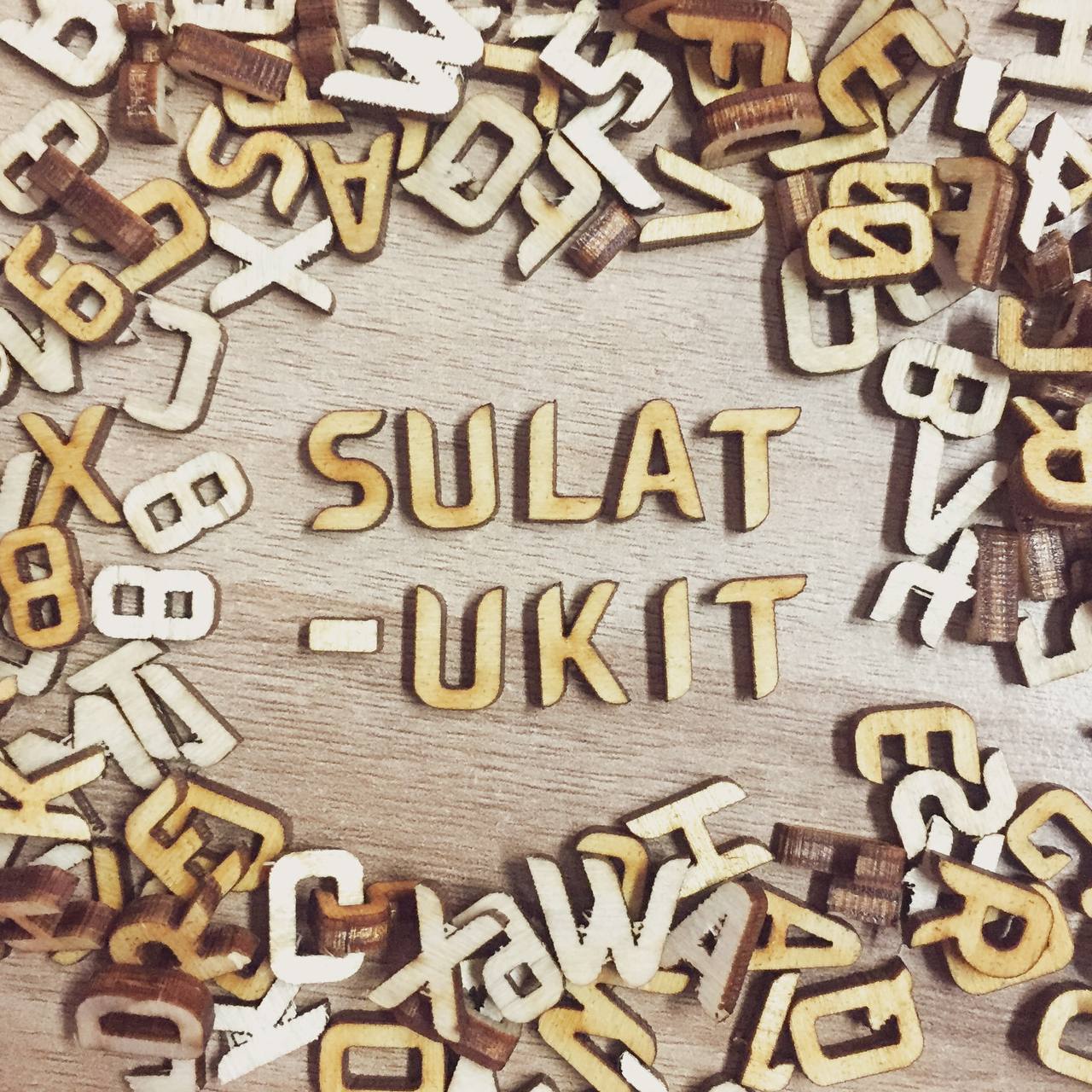

A high-powered laser beam is directed onto the material being cut, such as metal, plastic, wood, or fabric. The laser beam delivers an intense amount of heat, which rapidly melts, vaporizes, or burns away the material along the predetermined cutting path. The laser beam is controlled by a computer program that ensures accuracy and consistency in the cutting process.

Laser cutting is also known for its speed and efficiency. It enables rapid production rates, minimizing production time and costs. Moreover, it eliminates the need for traditional tooling, as the laser beam replaces the physical cutting tools, reducing setup time and enabling quick design changes

ADVANTAGES VS OTHER CUTTING METHODS

- Precision

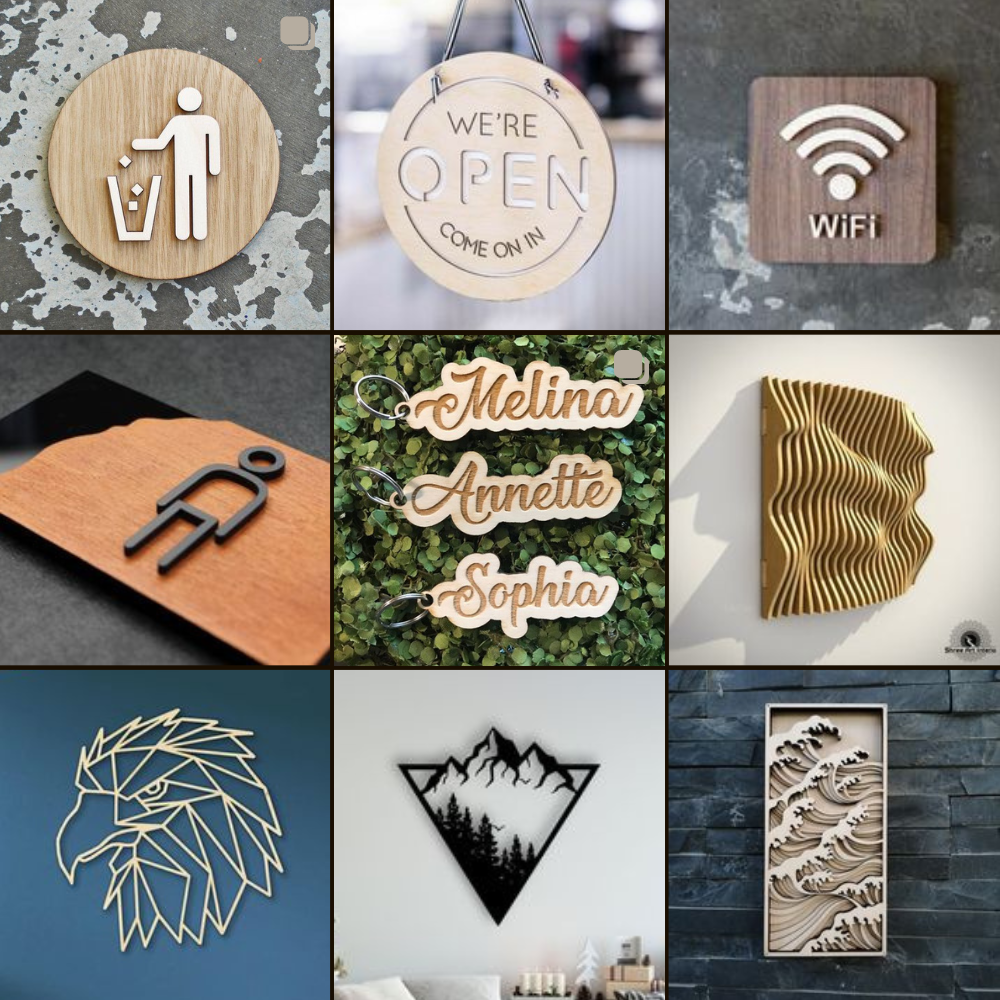

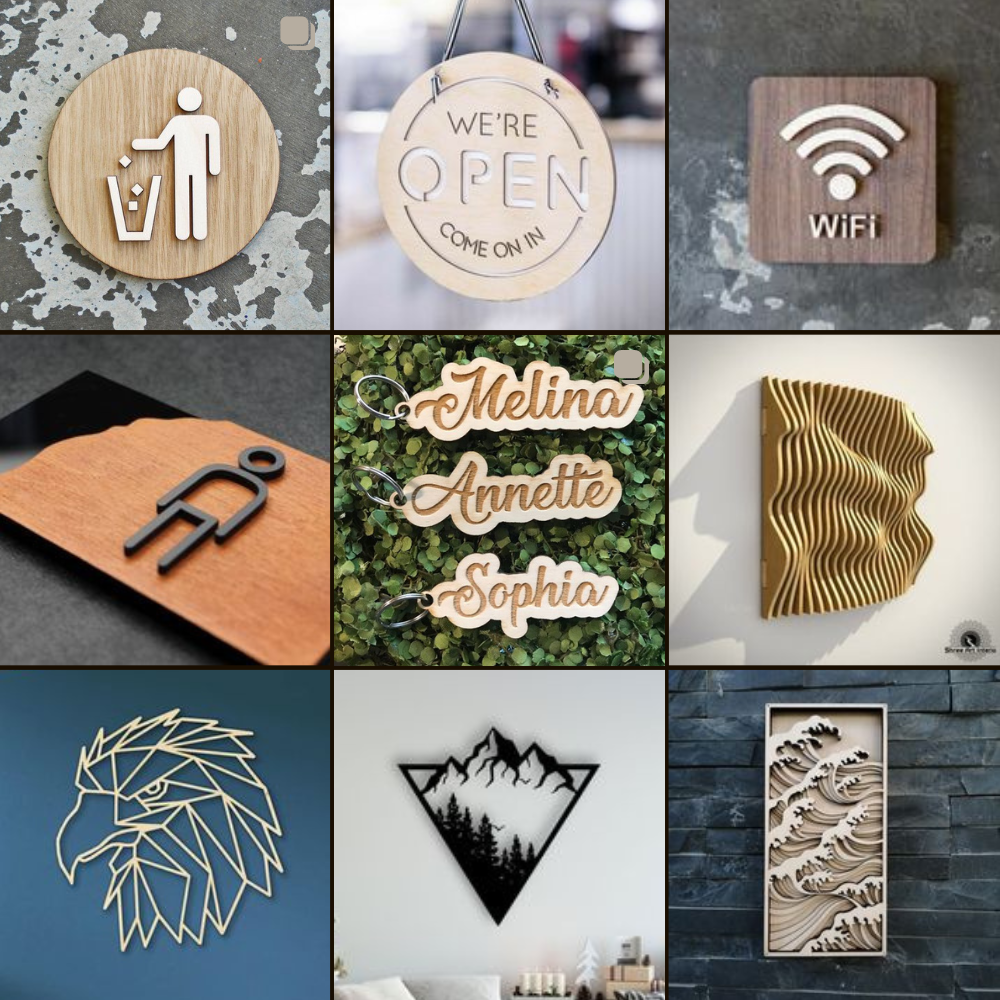

- Versatility

- Speed and Efficiency

- Minimal Material Waste

- Non-contact Cutting

- Complex Geometries

- Automation and Integration

- Minimal Heat Affected Zone

- No Tooling Cost